Stainless Steel Flange

Flanges are more important parts of pipelines. Some more important pipelines put forward higher requirements on flange materials during construction, such as higher strength, high-temperature resistance, high-pressure resistance, low-temperature resistance, corrosion resistance, wear resistance, etc. Carbon steel flange cannot fully meet the requirements of special physical and chemical properties, so stainless steel flanges appear.

Stainless Steel Flange is a flange made of stainless steel, referred to as ss flanges. The main standards are Stainless Steel Flange is a flange made of stainless steel material, which can generally be called stainless steel pipe flange, or stainless steel plate flange. Abbreviated as ss flanges. The main standards are ASME/ANSI B16.5 and ASME/ANSI B16.47, the pressure is from CLASS75 to CLASS2500, and the size is from 1/2″-60″. Stainless steel flanges have stronger and better corrosion resistance and are often used in pipelines with higher requirements.

Stainless Steel Flanges Standards and Specifications

| Specifications | ASTM A182 F304/F316/F321 |

| Size Ranges | From 1/2 inch up to 60 inch |

| Standards | ASME/ANSI B16.5 B16.47 |

| Pressure Classes | Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 and Class 2500 |

| Flange Facing | RF/ FM/ M/ T G/ RF / FF / RTJ |

| Type | WN SO SW TH BL RF FF MF RJT PL PJ/PR BL(S) |

Stainless Steel

Resistance to corrosion and staining, low maintenance, and familiar luster make stainless steel an ideal material for many applications where both the strength of steel and corrosion resistance are required. Moreover, stainless steel can be rolled into sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products.

The biological cleanability of stainless steel is superior to both aluminum and copper, having a biological cleanability comparable to glass. Its cleanability, strength, and corrosion resistance have prompted the use of stainless steel in pharmaceutical and food processing plants.

Mechanical Properties A182 F304/F316/F321

| ASTM A182 Grade | Minimum Tensile Strength in MPa | Minimum Yield point in Mpa | Minimum Elongation in % | Minimum Reduction of in min, % |

| ASTM A182 F304 | 515 | 205 | 30 | 50 |

| ASTM A182 F304L | 485 | 170 | 30 | 50 |

| ASTM A182 F316 | 515 | 205 | 30 | 50 |

| ASTM A182 F316L | 485 | 170 | 30 | 50 |

| ASTM A182 F321 | 515 | 205 | 30 | 50 |

Recommended service for stainless steel flange materials:

| Material | Material Group | Recommended Service |

| A182-F304 | 18% Cr, 8% Ni Stainless Steel | Corrosive services and atmospheres from -450°F to 1000°F (-268°C to 537°C) |

| A182-F316 | 18% Cr, 8% Ni, 2% Mo Stainless Steel | High resistance to corrosion from -450°F to 1000°F (-268°C to 537°C). |

ASTM vs. EN Stainless Steel Flanges Material Grades: Comparison European and American Standards

| Material number | EN | ASTM |

| 1.4541 X 6 CrNiTi 18 10 | X6CrNiTi18-10 | A 182 Grade F321 |

| 1.4571 X 6 CrNiMoTi 17 12 2 | X6CrNiMoTi17-12-2 | A 182 Grade F316Ti |

| 1.4301 X 5 CrNi 18 10 | X5CrNi18-10 | A 182 Grade F304 |

| 1.4306 X 2 CrNi 19 11 | – | A 182 Grade F304L |

| 1.4307 – | X2CrNi18-9 | A 182 Grade F304L |

| 1.4401 X 5 CrNiMo 17 12 2 | X5CrNiMo17-12-2 | A 182 Grade F316 |

| 1.4404 X 2 CrNiMo 17 13 2 | X2CrNiMo17-12-2 | A 182 Grade F316L |

| 1.4462 X 2 CrNiMoN 22 5 3 | X2CrNiMoN22-5-3 | A 182 Grade F51 (Duplex) |

| 1.4529 X 1 NiCrMoCuN 25 20 6 | X1NiCrMoCuN25-20-7 | UNS N 08926 |

| 1.4539 X 1 NiCrMoCuN 25 20 5 | X1NiCrMoCu25-20-5 | A 182 Grade F904L |

| 1.4547 – | X1CrNiMoCuN20-18-7 | UNS S 3125 |

Types of Stainless Steel Flanges

We have a large stock of ANSI/ASME standard 304 and 316 stainless steel flanges in many types and sizes. Quotations can be provided within 24 hours and shipped within 3 working days. The main types, materials, and specifications can be seen in the table below.

| TYPES | ASME/ANSI B16.47 Series A Weld Neck Flange | ASME/ANSI B16.47 Series B Weld Neck Flange | ASME/ANSI B16.5 Weld Neck Flange |

| SIZES | 26″-60″ | 26″-60″ | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900 | class75, 150, 300, 400, 600, 900 | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face | 1/16″ raised face | 1/16″ raised face |

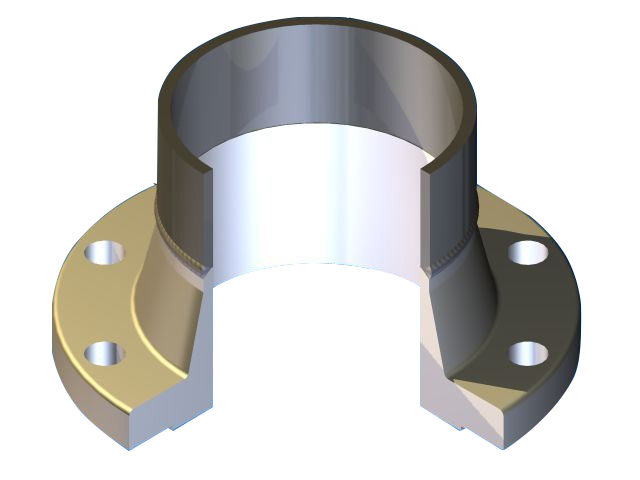

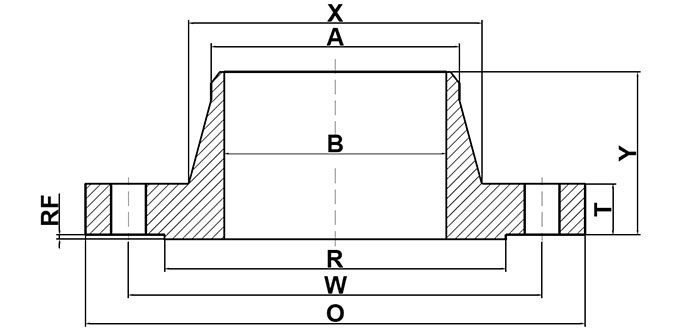

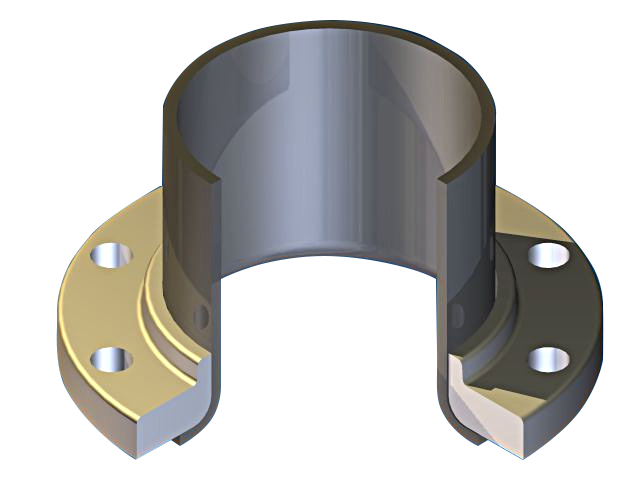

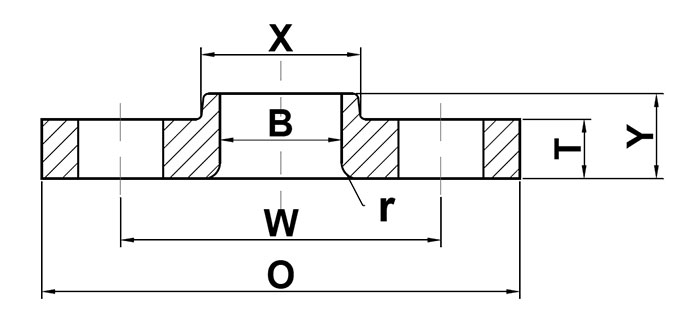

| TYPES | Slip-On Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

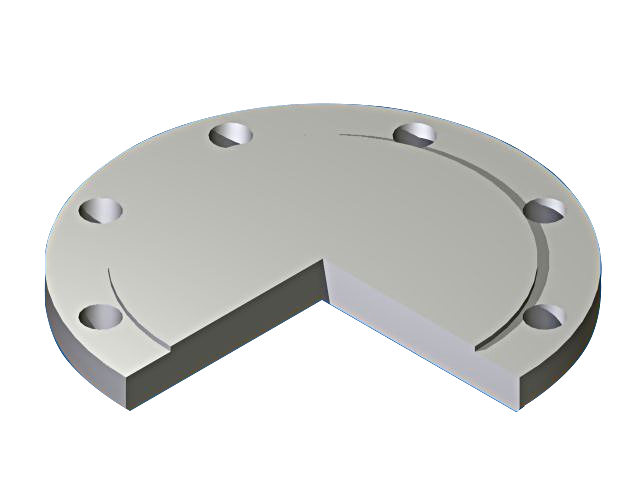

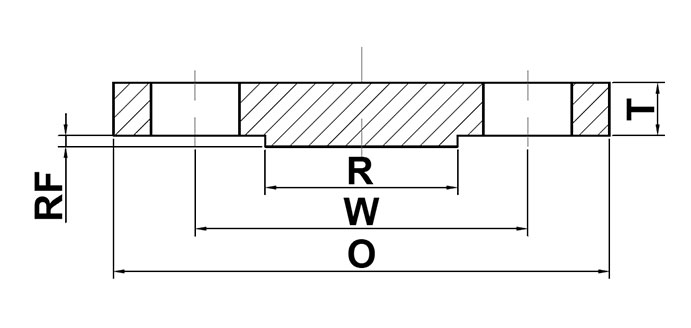

| TYPES | ASME/ANSI B16.47 Series A Blind Flanges | ASME/ANSI B16.47 Series B Blind Flanges | ASME/ANSI B16.5 Blind Flanges |

| SIZES | 26″-60″ | 26″-60″ | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900 | class75, 150, 300, 400, 600, 900 | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face | 1/16″ raised face | 1/16″ raised face |

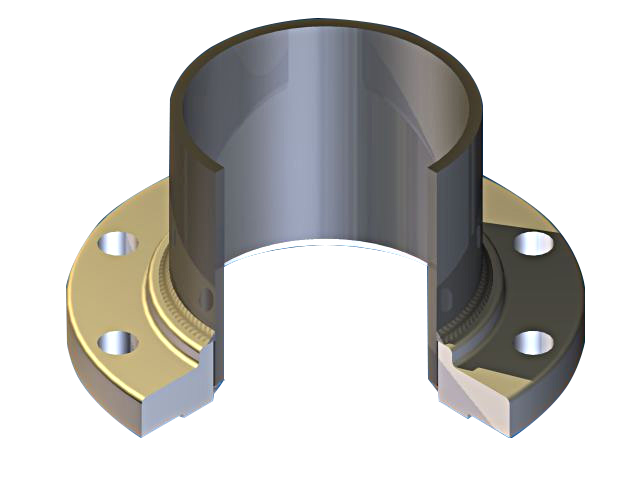

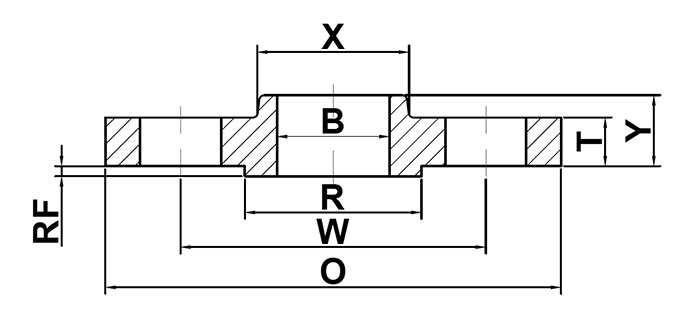

| TYPES | Lap Joint Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

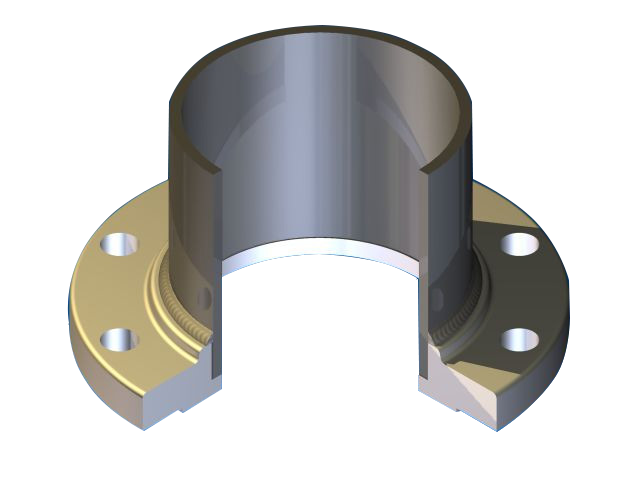

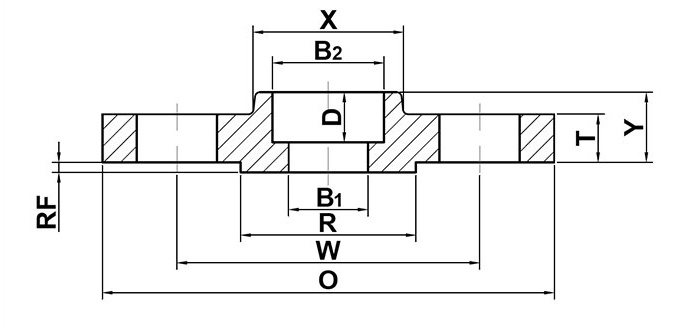

| TYPES | Socket Weld Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

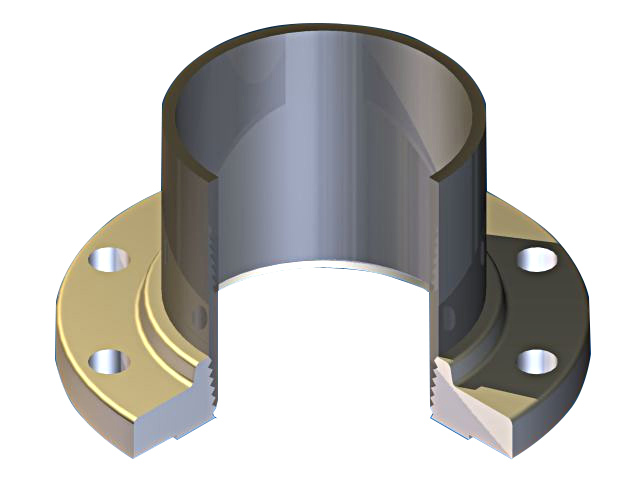

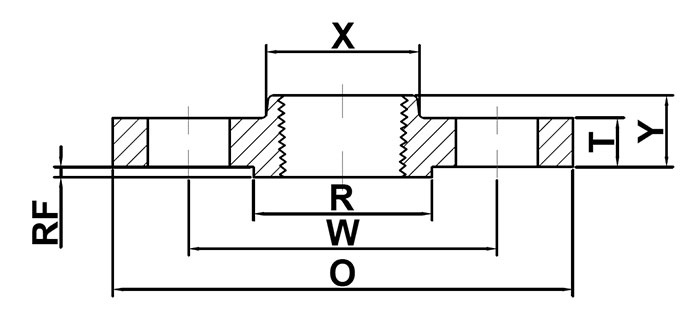

| TYPES | Threaded Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

Features of stainless steel flanges

Stainless steel flanges are highly resistant to rust, are much stronger and can outperform carbon steel flanges, and provide much more corrosion resistance than your carbon steel flanges.

Next, let’s talk about the advantages of using stainless steel flanges in detail.

1、Stainless steel is highly resistant to corrosion compared to other metals. This makes this material an ideal choice for pipe flanges and fittings.

2、Stainless steel is highly versatile. Different materials such as nickel, molybdenum, or nitrogen can be added to enhance the properties of stainless steel. You can utilize the different standard dimensions and specifications to order stainless steel flanges for a variety of environments. This allows the pipe flanges to fit a wider range of applications both indoors and outdoors.

3、The addition of titanium and molybdenum to stainless steel flanges increases its tensile strength, reducing the chance of warping or deformation.

4、Stainless steel flange fittings can withstand high pressure and temperatures. ASTM A182 flanges can handle extreme temperatures of about 500 to 800 degrees Celsius.

5、Stainless steel is a reliable material that is easy to maintain. Stainless steel fittings are highly durable. Your pipe flanges may last for decades, supporting liquid and gas flow within your piping system. Its stain and corrosion resistance properties mean that you may not have to replace the flanges for years to come.

6、Stainless steel flange is 100% recyclable. This actually makes stainless steel flange a more environmentally responsible choice in the long run. Approximately 50% of all stainless steel produced nationally comes from recycled scrap metal, meaning that these flange fittings can help you reduce your overall carbon footprint for a project.

7、With stainless steel being rust and corrosion resistant, the flanges provide easy access for inspection, modification, or cleaning. This can allow you to save time and money overall.

Application of stainless steel flange

As 304 stainless steel is a widely used chromium-nickel stainless steel with good corrosion resistance, heat resistance, low-temperature strength, and mechanical properties.Suitable for processing, storage, and transportation of food. Has good processing properties and weldability. Used in plate heat exchangers, bellows, household goods, building materials, chemicals, food industry, etc.

Compared to 304 stainless steel, 316 stainless steel materials have additionally Nickel and Molybdenum, which in China is called 18Cr-12Ni-2.5Mo steel. So normally it has extra Mo 2.0 to 3.0 percent than 304 steel. And this Mo is an element to offer better resistance to high temperatures.

Therefore, It is particularly good in corrosion resistance, atmospheric corrosion resistance, and high-temperature strength. It can be used under severe conditions in which it has excellent work hardening properties (non-magnetic).

316L stainless steel flange has a good anti-corrosion effect, better than 304 in seawater and other various media. So it is also regarded as ”marine grade” stainless steel, but it is not resistant to warm seawater.

316 SS flange used for equipment resistant to sulfuric acid, phosphoric acid, formic acid, and acetic acid. Applications include marine, pumping, chemical production, food industry, irrigation, and other stainless steel pipeline systems.

How to choose stainless steel flange

There are many types of stainless steel flanges. Having so much to choose from, how do you decide where to place your money? Here are four factors to consider.

1、Fluid Type

The type of fluid you are conveying in your pipeline dictates what flange to use. Consider its temperature and pressure so that a flange can serve you longer.

2、Integrity

If you are conveying toxic fluids, you want flanges that guarantee zero leaks. Otherwise, the fluids could cause soil contamination and other environmental risks. In that case, choose tighter and stronger flanges.

3、The Risk of Contamination

Some pipelines convey sensitive fluids such as in pharmaceutical applications. You have to ensure that your flanges don’t contaminate the fluids.

4、The Law

The fugitive emission laws in your country are another factor to consider. Violating these laws could land you in legal trouble, which is not good for any company.

Referred Standards

B16.5 Dimensional standard for steel pipe flanges and flanges fittings

B16.47 Large diameter steel flanges B16.47

We have an extensive inventory of multiple stainless steel flanges. Most of our high-quality, flanges and gasket kits are ready to ship upon request. Speak to one of our specialists and find out which flange pOne of the key factors to keep in mind when purchasing pipe flanges is the material choice. Stainless steel is a strong, durable, corrosion-resistant metal, making it an excellent choice for flange fittings in the oil and gas industry. If you want to take advantage of these benefits, reach out to YANHAO. our products are available to meet your flange and piping specifications. View an overview of our flange offerings.