What is the main function of pipe flanges?

A pipe flange is a disc, collar, or ring that attaches to a pipe with the purpose of providing increased support for strength, blocking off a pipeline, or implementing the attachment of more items. Pipe flanges’ primary purpose is joining two distinct pipes or pieces of machinery. They are usually welded or screwed to the pipe end and are connected with bolts.

A gasket is inserted between the two mating flanges to provide a tighter seal. most flanges are made of metal or plastic. These are flat components that are fastened to the ends of two pipes or pieces of equipment in order to allow them to be bolted together.

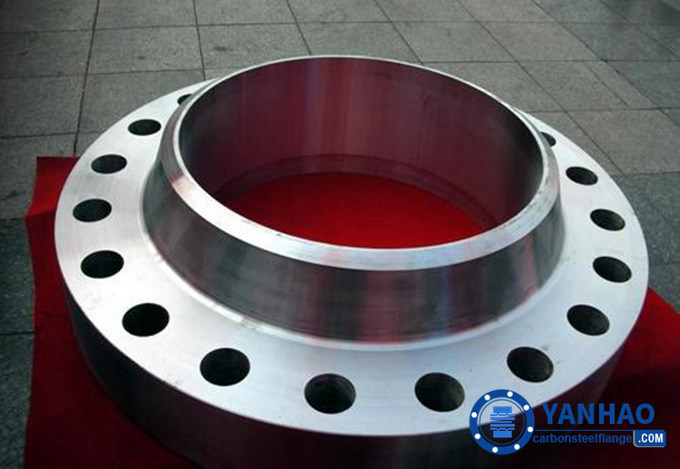

A “flange” is a projecting rim, collar, or ring on a shaft, pipe, machine housing, cast, or formed to give additional strength or stiffness, with a supporting area, or that provides a place for the attachment of other objects.

The main function of pipe flanges: they are used to connect valves, pipes, pumps, and other gear to make a pipework framework. Regularly ribs are welded or strung, and two spines are associated together by blasting them with gaskets to give a seal that gives simple admittance to the channeling framework. A line spine is a strategy for interfacing pipes, valves, siphons, and other hardware to frame a channeling framework. It additionally gives simple admittance to cleaning, examination, or adjustment. Ribs are typically welded or screwed. Line flanged joints are made by darting together two ribs with a gasket between them to give a seal.

These flanges are either custom with dimensions provided by the customer or they are manufactured according to published specifications.