Flange related knowledge

We don’t see much about flange in our daily life, and many people may not know it very well. Today we will talk about flange-related knowledge!

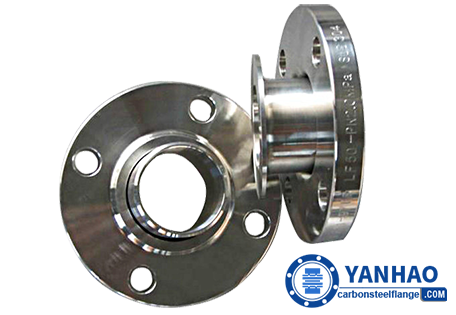

For those who are engaged in mechanical or engineering installations, the flange should be very familiar. It is a disc-shaped part and is generally used in pairs. It is mainly used for connecting parts between pipes and valves, between pipes and pipes, and between pipes and equipment, and plays a sealing role.

Origin of flange

The flange is also called a flange convex disc or convex circle. The flange is the part that connects the shaft and the shaft. It is mostly used for the connection between pipes, fittings, or equipment. As long as the bolt connection is used around the two planes, the connected parts that are closed at the same time can be collectively referred to as flanges.

The flange was invented in 1890 by an Englishman named Elkhart. At the same time, a casting method of the flange is also proposed. But it was not widely used for quite some time later. Until the beginning of the 20th century, flanges were widely used in special mechanical equipment and pipeline connections.

Flange type and structure

The types of flanges can be divided into welding neck flanges, slip-on flanges, socket welding flanges, threaded flanges, blind flanges, and so on.

Although there are many types of flanges, each type of flange consists of three parts, first the flange itself, which will be placed on the pipe, and then the gasket installed between the two flanges, which can provide a tighter and more effective seal. The last thing is the bolts that connect the two flanges.

Flange production process

There are two main production processes for flanges: forging and casting.

The forged flange is hammered by the forging press countless times so that the internal structure of the steel becomes tight. Therefore, the mechanical properties of the forged flange will be better and the strength will be higher. The forged bars are mainly used in our pipes with higher pressure.

Casting flanges have the characteristics of low manufacturing cost and high efficiency and can manufacture methods with complex shapes. Cast flanges are mainly suitable for those pipelines with lower pressure.

Flange material

The most common production material for flanges is carbon steel, but can also be made of stainless steel, alloy steel, or other materials.

Flange application

Although small parts such as flanges are inconspicuous in the entire product, the role of flanges is very important. In the future, with the development of flange materials and processes, it can ensure more precision and firmness in the entire street connection process, and ensure people’s safety and reliability. Because there are many applications between these devices and pipelines. Therefore, the two planes are connected by bolts. And the connecting parts with sealing function are called flanges. Due to the important role played by flanges and their good overall performance, they are widely used in chemical, petrochemical, firefighting, and drainage industries.

The above is the knowledge about flanges compiled by YanHao for you. If there is an error, you can leave a message to us.