Carbon Steel Flange

Carbon Steel Flanges is a flange made of carbon steel, referred to as CS flanges. Carbon steel pipe flanges work perfectly at low temperatures and the finest quality material and advanced techniques are used. As per the national and international standards these flanges are manufactured as ASME/ANSI B16.5, B 16.47, etc. Quenching carbon steel slip-on flanges are where the steel and cast-iron alloys are strengthened and hardened. This is a product that has good ductility power, toughness, and machinability, the pressure is from CLASS75 to CLASS2500, and the size is from 1/2″-60″.

As compared to stainless steel flanges, the carbon steel pipe flanges have a higher carbon content. This high content of carbon is what gives the carbon steel plate flanges a lower melting point. Increased carbon content in the cs slip-on flanges makes them more malleable. Further, these flanges have good durability and offer better heat distribution properties.

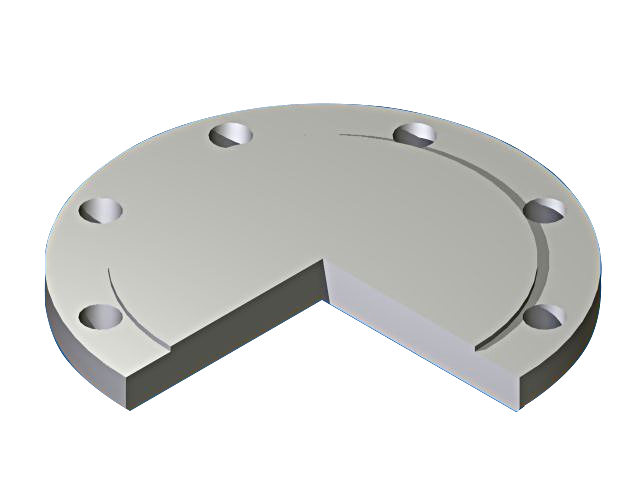

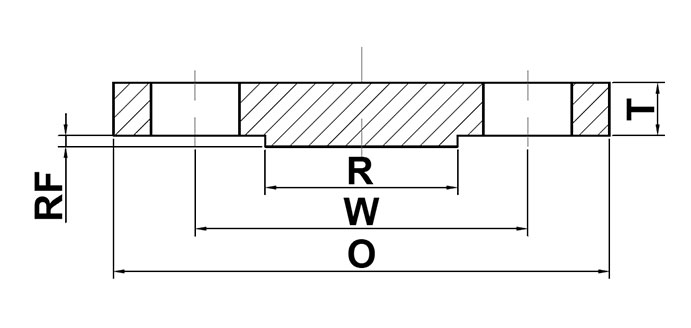

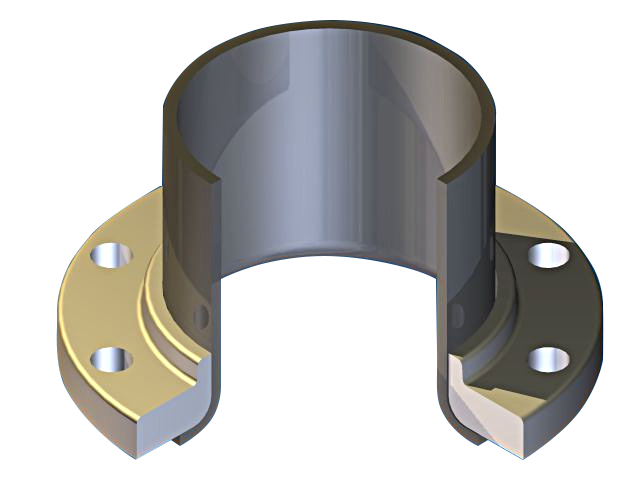

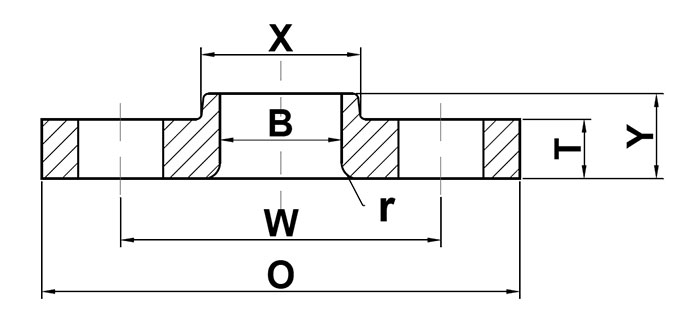

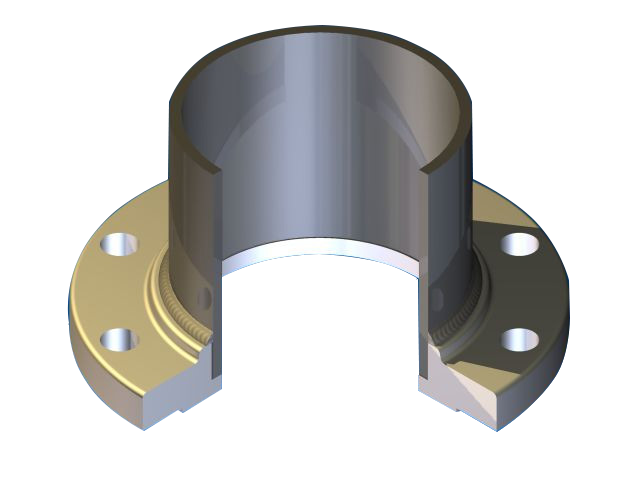

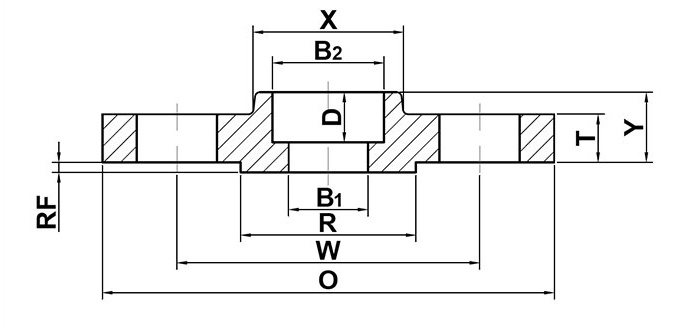

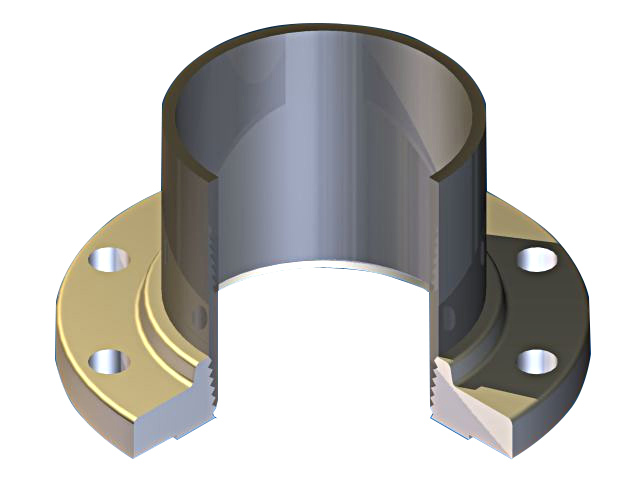

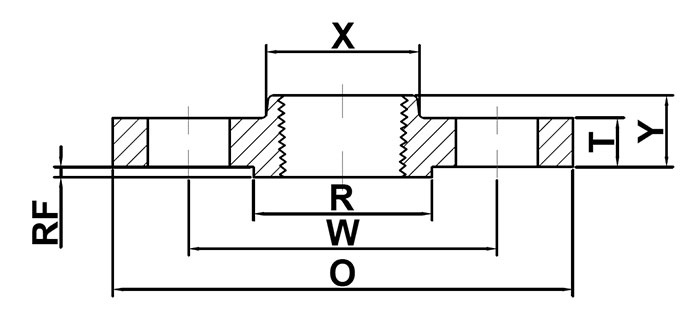

Carbon Steel Forged Flanges are primarily used in petrochemical-, pressure systems, or pipe joining systems. The pressure rating is determined by the table or drilling, i.e. ASA150, ASA300, or ASA600. Available Carbon Steel Forged Flanges include blind/blank, screwed/threaded, slip-on/weld-on, socket weld, or weld neck.

Carbon Steel Flanges are forged carbon steel designed to connect sections of pipe or join pipe to a pressure vessel, valve, pump, or any other equipment. In the case of Carbon steel flanges, ASTM A3015, ASTM A182, ASTM A694, and ASTM A105 are the most common grades available. The carbon content is up to 2.1% in weight in carbon steel flanges.

Carbon Steel Flanges Standards and Specifications

| Specifications | ASTM A105, ASTM A350, LF1/2, ASTM A181 |

| Size Ranges | 1/2″-60″ |

| Standards | ASME/ANSI B16.5 B16.47 |

| Pressure Classes | Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 and Class 2500 |

| Flange Facing | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Type | Slip-on flanges, Weld neck flanges, Socket weld flanges, Lapped joint flanges, Threaded flanges, Blind flanges. |

carbon steels

According to the content of carbon in its alloy, these steels are classified into Three groups of carbon steels:

- Low carbon steels (C < 0.25%) 低碳钢(c < 0.25%)

- Medium carbon steels (C =0.25% to 0.55%) 中碳钢(c = 0.25% ー0.55%)

- High carbon steels (C > 0.55%) 高碳钢(c > 0.55%)

Chemically, Low carbon steels contain less than 0.25% carbon in their alloy. While they cannot be strengthened by heat-treating the alloy, the carbon steel threaded flange can be strengthened through cold working). Although low carbon material is relatively soft and weak, the alloy has outstanding ductility and toughness. Additionally, it has good machinability, good formability, and weldability. They are also relatively inexpensive to produce and the carbon steel flange price is lower.

Medium carbon steels have carbon content falling in a range of 0.25% and 0.60%. These steels may be heat-treated by austenitizing, quenching, and followed by tempering in order to improve their mechanical properties. The heat-treated medium carbon steels provide the tremendous load-carrying ability and have good toughness and ductility. They have relatively good strength, can be hardened by quenching.

The properties of High Carbon steel flanges include hardness, high strength and wear resistance, moderate ductility.

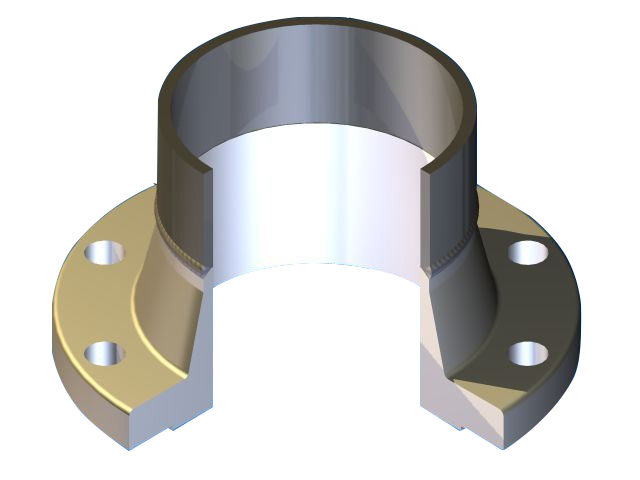

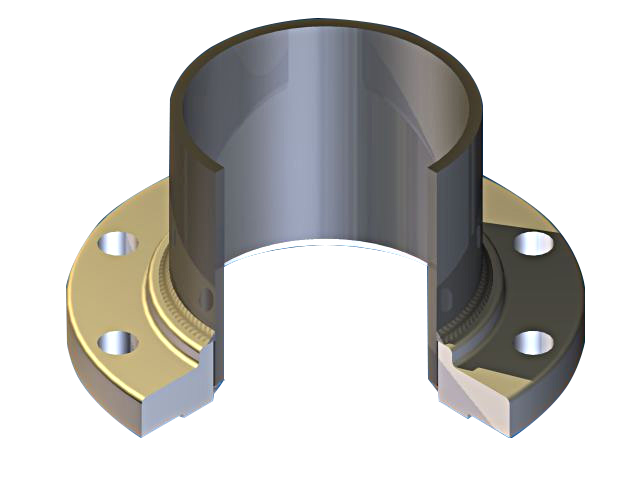

Type of carbon steel flanges

The chemical composition and the mechanical properties of the three main carbon steel flanges material grades:

- ASTM A105 (high-temperature carbon steel) to match A53, A106, API 5L carbon steel pipes

- ASTM A350 LF1, LF2, LF3 (low-temperature carbon steel) to match ASTM A333 pipes

- ASTM A694 F42, F52, F60, F65 (high-yield carbon steel to match API 5L X42, X52, X60, and X65 steel pipes

Carbon Steel A105 Flanges

Carbon Steel A105 Flanges have forged carbon steel piping components, i.e., they are used in fittings, flanges, valves, flanges, and similar parts, and in pressure systems at ambient and higher-temperature service conditions. The Carbon Steel A105 Flanges are operated under temperatures 500 Degree to 550 Degree. It is used in Hydro-carbon, Marine engineering processing. Heat exchangers, pumps manufacturing, petrochemical plants, valves manufacturing, oil & gas equipment, nuclear power projects, and so on. There are various types of flanges, such as Plate Flanges, Weld Neck Flanges, Blind Flanges & many more.

Carbon Steel A350 LF2 Flanges

The Carbon Steel A350 LF2 Flanges houses many grades of carbon and ring-rolled flanges, valves, low-alloy steel forged, and forged fittings for low temperatures. These flanges are extensively known for their temperatures and pressure resistance, strength, and durability. The Carbon Steel A350 LF2 Flanges provides maximum machinability when it is annealed, normalized, or forged, thus gaining moderate strength and offering leakage-proof connection at low cost. These flanges are generally more in demand than conventional austenitic stainless steel, due to their higher hardness property.

Carbon Steel A694 Flanges

This is a rigorous carbon steel A694 flanges material than the above three. It is stringent to the high-pressure fluid transmission of oil and gas piping. And because of this property of the steel grade, manufacturers have to develop even stronger steel to withstand both cryogenic and high temperatures. As the carbon content increases, the steel gets harder and stronger after giving it heat treatment. On the other hand, it becomes less ductile. Whereas if no heat treatment is given, the higher carbon reduces its weldability.

Carbon Steel Flanges Application Industries

Carbon Steel Flanges are widely used in various industries including Pulp and Paper Industry, Chemical Equipment, pharmaceutical, Pharmaceutical Equipment, Petrochemicals, Gas Processing, Power Generation, Sea Water Equipment, Heat Exchangers, Condensers, Specialty Chemicals, Off-Shore Oil Drilling Companies, and others.

Carbon Steel Flange Price

we produce flanges in different types and material grades. The carbon steel flanges have carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium depending on the material grade. The Carbon Steel Pipe Flange Price List varies according to the material grade as well.

| Carbon Steel Blind Flange Price | USD $ 14~USD $ 472 |

| Carbon Steel Weld Neck Flange Price | USD $ 1.8~USD $ 460 |

| Carbon Steel Slip On Flange Price | USD $ 2.2~USD $ 239 |

ABOUT FORGED STEEL FLANGES

Manufacturers develop flanges of many materials that match the material that you use for pipes and fittings. There are many ways you can manufacture flanges, the most prominent ones being casting and forging.

Forged steel is the excellent mechanical property of almost any flange product. The process of manufacturing happens with carbon steel, alloy steel, or stainless steel. The raw materials are beaten and cut into shape via hammers and presses, which helps to get rid of defects and blocks.

There is another type of flange that is known as killed Carbon Steel Forged Flanges. They are destroyed in the melting process. Due to the addition of manganese, silicon, and aluminum during the production of steel, deoxidation takes place. Carbon Steel Plate Flanges are welded onto the pipe which helps in bolting and connecting one pipe to the other. It displays good ductility, and toughness. These Carbon Steel Pipe Flanges also work well in low temperatures. They are used in fuel and water pipelines.

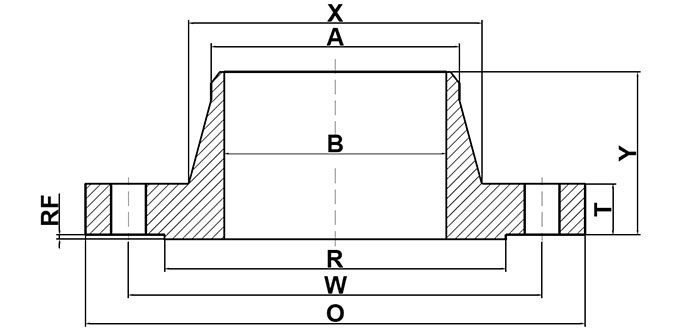

| TYPES | ASME/ANSI B16.47 Series A Weld Neck Flange | ASME/ANSI B16.47 Series B Weld Neck Flange | ASME/ANSI B16.5 Weld Neck Flange |

| SIZES | 26″-60″ | 26″-60″ | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900 | class75, 150, 300, 400, 600, 900 | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face | 1/16″ raised face | 1/16″ raised face |

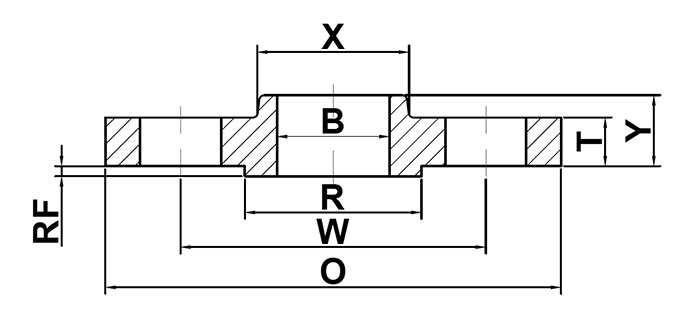

| TYPES | Slip-On Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

| TYPES | ASME/ANSI B16.47 Series A Blind Flanges | ASME/ANSI B16.47 Series B Blind Flanges | ASME/ANSI B16.5 Blind Flanges |

| SIZES | 26″-60″ | 26″-60″ | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900 | class75, 150, 300, 400, 600, 900 | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face | 1/16″ raised face | 1/16″ raised face |

| TYPES | Lap Joint Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES | Socket Weld Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

| TYPES | Threaded Flanges |

| SIZES | 1/2″-24″ |

| PRESSURE | class150, 300, 400, 600, 900, 1500, 2500 |

| MATERIAL | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8; |

| TYPES OF FLANGE FACES | 1/16″ raised face |

Carbon Steel Pipe Flanges Packaging

All our Carbon Steel Flange are manufactured in accordance with international standards. Carbon Steel Pipe Flange is packaged to ensure that there is no damage during transit. In the case of exports, standard export packaging is done in wooden cases. All Carbon Steel Plate Flanges are marked with Grade, Lot No, Size, Degree, and our trademark. On special requests, we can also, make custom marking on Carbon Steel Flanges.

Differences between forged steel flange and cast iron flange

1. Forged steel flange has better performances than cast iron flanges, lower carbon content so is harder to get rusty. Better shape with smooth streamline, higher mechanical strength because of the higher steel structural.

2. Forging process will not make a big or uneven brain, the cost is higher than cast iron.

3. Forged steel is easy to be cut and can take higher tensile strength.

4. Casting iron could be made to different and complicated profiles, cost lower.

5. Cast iron steel exists air bubble, harmful defects, where forged steel flange don’t.

6. Using a Centrifugal machine will produce higher precision cast iron flange than normal cast flanges.

7. Forged steel flange could be used in higher pressure pipelines, where cast iron flange only could be used in non-pressure pipelines, otherwise will cause leaking problems.

HOW TO PREVENT CARBON STEEL FLANGE FROM RUST?

Carbon steel can get rust, but you can prevent it using the following solutions:

1, Oil varnishing: It helps to lubricate the carbon steel. Oil forms a protective barrier against rust and allows them to move with friction.

2. Anti-rust painting: Painting a carbon steel flange helps to cover metal components in a protective layer. It helps to prevent moisture from reaching the metal and therefore prevents rust and general corrosion.

3. Electric zinc-coated (Yellow or white zinc): Galvanising or electric zinc-coating is one method to prevent rust. It is easy to stop the reach of water and oxygen underneath the metal by coating it in a thin layer of zinc.